We deliver proven performance, next generation innovation and mission-critical reliability.

With more than three decades of experience manufacturing ships for commercial and defence customers, and production facilities in Australia, the United States, Philippines and Vietnam, we are renowned for delivering proven and reliable naval vessels.

An efficient, modular approach

At the heart of our manufacturing approach, is a commitment to quality, efficiency and safety, combining advanced technologies with smart manufacturing processes to deliver vessels.

We take a modular approach to our shipbuilding operations across the globe. This involves building prefabricated modules of a ship indoors and transferring to our large vessel assembly bays to complete the manufacture of each vessel.

Automation drives productivity and accuracy across the value chain, from robotic welding, to automated material handling and computer controlled cutting and forming. Our systems minimise error and reduce waste whilst allowing our skilled tradespeople to focus on innovation and craftsmanship.

Through the application of digital twin technology and with a digital thread connecting each stage of the manufacturing process stage, our customers can be assured of a quality product, that is built on time and on budget.

Ensuring our customers stay ahead in an evolving maritime world

We lead the operation of the Navy Additive Manufacturing Center of Excellence (AM COE) in Danville, Virginia, a national hub dedicated to advancing the United States Navy’s use of additive manufacturing for submarine components. Through this effort, we are building a qualified national vendor network with advanced additive manufacturing capabilities to produce critical parts for the fleet.

Our advanced technology team in Charlottesville, Virginia, manages the AM COE and brings extensive expertise across multiple additive modalities and materials, including Laser Powder Bed Fusion (LPBF), Wire Arc Additive Manufacturing (WAAM), Wire Laser Additive Manufacturing (WLAM), and exploratory use of Cold Spray Additive Manufacturing (CSAM).

Strengthening Australia’s sovereign naval capability

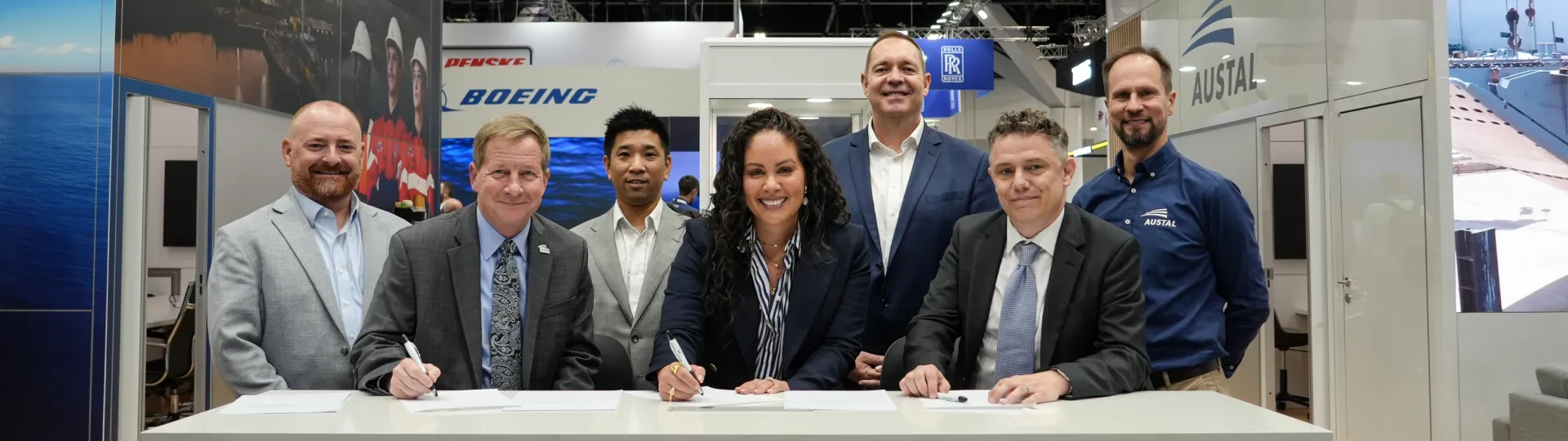

We've partnered with ASC to advance additive manufacturing and support Australia’s naval capability.

The two main benefits to a modular manufacturing approach are fast product and cost efficiency. This approach allows multiple sections of a ship to be built in parallel, whilst parallel workflows and standardised work processes minimise waste and reduce labour.

Upon arrival in the final assembly bays, modules are lifted into place and welded to the existing structure. Work is completed on the pipes, heating, ventilation and air-conditioning (HVAC) ductwork, machinery, electric cables, equipment and outfitting as we prepare the ship for launch.